The following details explain much of the full-length YouTube video “Bamboo Fly Fishing Rod – The Process of Making Oneness Rods”. Video link: https://youtu.be/qvupU5fJDMo

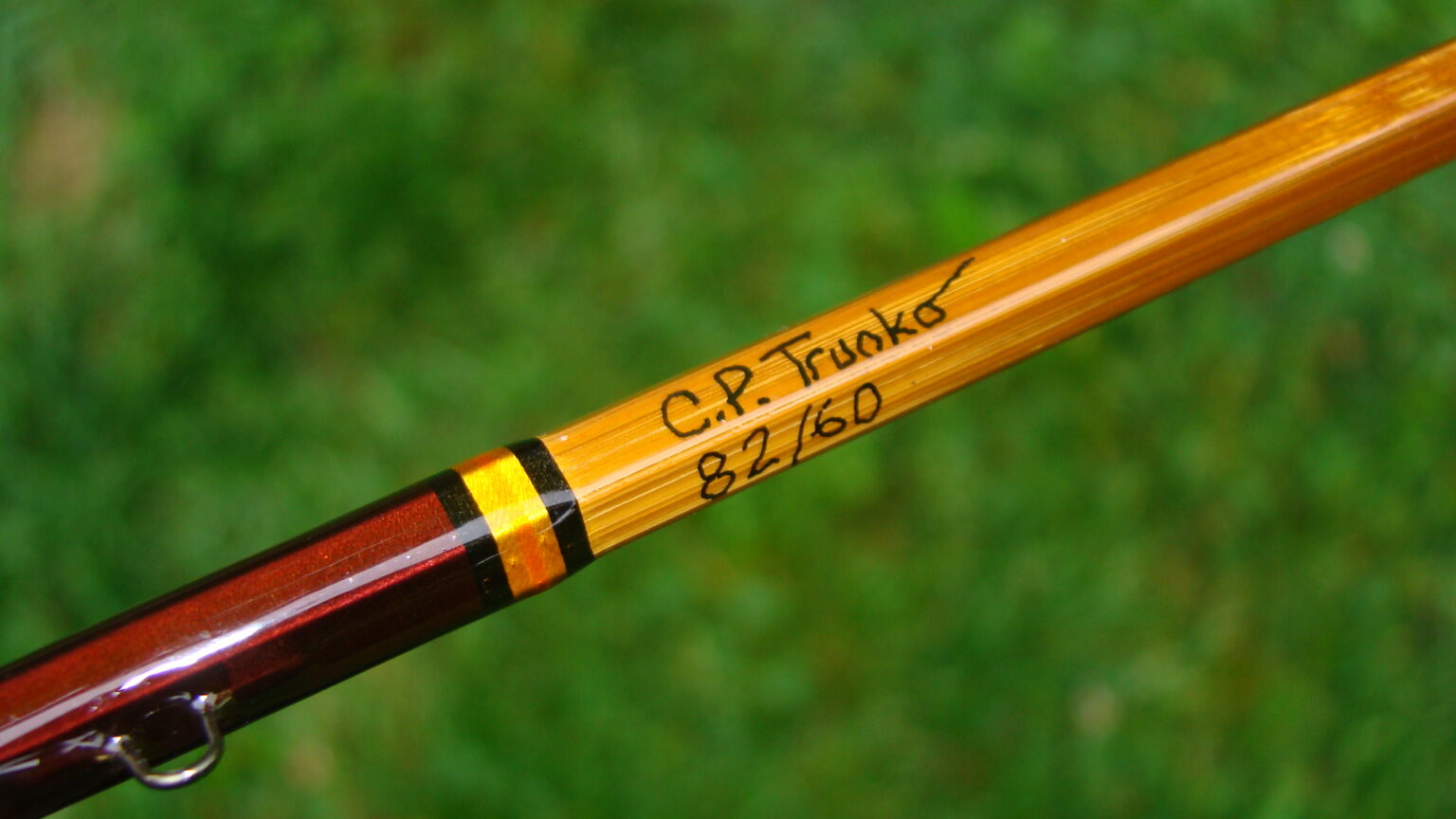

Each Oneness Rod starts with a culm of Chinese Tonkin Bamboo. Using all manual hand tools the bamboo is made into a one-piece 6 foot full length hexagon fly rod blank. The nodes of the rod are typically staggered 3×3 and spaced an inch and a half apart, and never positioned within a foot of the tip-top. The culm is cut to length, then split in half lengthwise; and the nodal dams are removed with a mallet and gouge chisel. I then slowly torch only the inner pith side of the halved culm working middle-out in what I refer to as “crystallizing the sap”. Sap moisture will be bubbling out the end of the culm a couple inches ahead of the torch flame. From weight studies I believe this method removes intracellular moisture; which is moisture within the individual cells. It does not add any color or darkening to the bamboo. The culm is then split into strips and any remaining nodal dams are planed away. Each node is lightly hand filed to remove any sheath scarred enamel, and then heated over an alcohol flame until softened, and the remaining nodal hump is pressed flat between the smooth jaws of a bench vise. Each strip will require straightening and twists removed by again heating over an alcohol flame, and using various straightening hand tools and jigs. The strips are then rough planed into straight triangular splines and bundled and bound together into the six splines that will ultimately make up that hexagon rod blank. All the bundles for the rod making season are then hung together in a sealed tube of heated ammonia hydroxide for one week. Even though full brown-toning occurs within the first ten minutes by pulling out all the natural tannins of the bamboo making it a rich filbert nut brown color, the full week ensures complete ammonia saturation throughout the bamboo splines. Based on studies performed by the USDA and Forest Service I believe impregnating the bamboo with the ammonia assists in preventing potential wood rot and decay by killing any fungal rot causing mold spores that may exist in the pores of the bamboo, as it is not uncommon to have culms with mold growth within the confined chambers between the nodes of the bamboo. Bamboo is a giant grass, and so bamboo fishing rods are made of Organic material; which is also likely why their action and feel is so “lively”. The ammonia saturated bundles of rough splines are then oven-tempered to a gradual climb in temperature to 350°F to the point when ammonia smell is no longer present and replaced by a uniquely sweet chestnutty aroma, and the intercellular moisture is removed; which is moisture surrounding the individual cells. This heat treatment also tempers the bamboo splines making them more stiff and elastic. The tempered rough spline bundles are then allowed to cool slightly before storing them in a sealed tube with a tea ball containing silica gel crystals, which absorbs any moisture that may still be present. During the months of lowest humidity each of the bundles of tempered rough splines will be removed individually, and on-that-day those six splines will be hand planed to the final taper for that serialized hexagon rod blank. The tapered splines are then bundled back together in the alternating node pattern of the finished rod blank. The bundle is taped in a dozen places along the length of the blank, and each wrap of tape is then slit with a razor blade, and the tapered bundle is fanned open flat on the work table. The opened flat bundle is then planed along the entire length of the six tapered splines to remove the core apexes. This ensures a tight fit between the glued surfaces of the tapered splines the full length of the hexagonal blank. Two-part epoxy adhesive is brushed along the entire length of the opened flat blank; and once applied is then rolled-up into a wet spineless rod blank. The glued blank is then run through a blank binder twice wrapping the blank with a binding cord in opposite directions, and then tied off with half hitches. The flimsy wet bound blank is then rolled on a glass surface like a cue stick working out any kinks from tip to butt in order to straighten it, and then hung to cure in a heated curing cabinet for one week. The binding cords are removed after 24 hours and the blank is returned to the curing cabinet for the remainder of the week. Once fully cured the dried epoxy is sanded from the six sides of the hexagon rod blank, and is filed away from the butt end. The rod blank taper is then verified using a dial thickness gauge comparing the measured flat-to-flat dimensions to that of the plotted taper curve as designed. At this point the blank can be straightened further as needed, and twisting of the blank can also be addressed using a heat gun and special hex clamp jigs. Three to four sanded blanks are then placed together in a tube of heated wood stabilizing resin for one week to be fully plasticized. This process is one method also referred to as “impregnating” by other bamboo rod makers. After one week the plasticized blanks are then transferred to the heated curing cabinet for another week to fully cure. Once cured the plasticized blanks are then rubbed-down with steel wool to remove dried resin residue, and it is now a completed blank. The plasticized blank is slightly heavier and even more stiff than before entering the stabilizing tube, as well as having a slight sheen and tad bit darker in color. Cork handles are typically made during the weeks of blank curing and plasticizing. Cork rings are selected using a ring gauge to best avoid any imperfections in the finished cork handle. The rings are bored and glued together with wood adhesive on a mandrel; then allowed to dry overnight pressed in a clamping jig. The cork handle is then shaped on a lathe and sanded smooth. Reel seat butt cap “coins” are made from an Ohio buckeye tree burl that’s been vacuum stabilized in wood resin and turned, sanded, and cut to thickness on the lathe; and then epoxied into the end of the reel seat rubber butt cap. The completed blank is then flexed on the work table to identify the spine or “backbone” of the blank indicating which side of the hexagon blank to mount the guides; being opposite the backbone. The cork handle, traditional black anodized aluminum reel seat, rubber winding check, and rubber butt cap with Ohio buckeye burl coin (note: next generation Oneness Rods will instead have an anodized aluminum butt cap) are all then epoxied to the blank; and adjusted and clamped in an alignment fixture for 24 hours to fully cure. Once cured the blank assembly is ready to have the tip-top fitted, and the hook holder and guides located and wrapped to the blank using Kimono silk threads. Just a note; the colors of the silk wraps on Oneness Rods reflect that of my late grandfather Mickeys’ pool cue wraps. Three coats of color preserver are applied to the silk wraps, and allowed to dry between each coat. A single coat of polyurethane is then applied over each of the silk wraps, and once dry the Oneness Rods brand gold logo is placed. The remaining two coats of polyurethane are then applied over the silk wraps. Once fully dried the rod Power and Action Angle is then recorded using Dr. William Hanneman’s Common Cents System of rod testing. A photo is taken of the rod weighted in its Stiffness Profile and saved as the serial number of the rod; which is later used for customer reference on eBay. The bare bamboo rod is then wiped-down with clean denatured alcohol and is inked along three flats on the underside of the rod blank with “C.P.Trunko”, the recorded CCS of Power in grams / Action Angle in degrees, and serial number of the rod.

Example of serial number is F112004, where “F” indicates Fly rod (since I have also made Spinning rods), and the numerals in groups of two is the month of November, the year 2020, and the 4th rod made that season. The serial number identifies the plotted curve or profile of the rod blanks’ taper. Lastly four coats of heated spar varnish is applied to the full length of rod from winding check to tip-top including the winding check and all polyurethane coated silk wraps; and allowed to dry twelve hours between applications. The silk wrap thread terminations and any air bubble imperfections are sanded smooth before applying the final two coats of heated spar varnish. The layers of spar varnish provide a hardened finish over the softer polyurethane coated wraps that fully cures over a few weeks hanging in a low humidity drying cabinet before it is ready to be test cast and eventually fished. Though difficult to capture in photos the finished bamboo rod has a rich orange hue that is quite brilliant in the sunlight. A “Loop” of fly line backing is attached to the tip-top of each Oneness Rod, and is used to hang the rod to cure once finished. Simply pass the rod tip-top through the Loop, and then pinch the Loop and pass it up through the tip-top eye; and allow the rod to hang free. The Loop should be “looped” around the tip-top barrel at the end of the rod and not around the eye of the tip-top, to hang in a true vertical straight position. It is without any doubt the single best way to store your one-piece bamboo fishing rod when not in use. The Loop allows your bamboo fly rod to hang free in a straight vertical position when stored. There is also a Rod Storage Tube available, and is recommended for long term storage and traveling with your Oneness Rod.